16F18855 with 5K pot

So I have 2 rotary pots that refuse to go down to ADC=0. So I thought it was a perfect occasion to practice using Vref-.

I've gutted my code so there's only 1 pot being scanned:

Code:

#CONFIG

__config _CONFIG1, _FEXTOSC_OFF & _RSTOSC_HFINT32 & _CLKOUTEN_OFF & _CSWEN_OFF & _FCMEN_ON

__config _CONFIG2, _MCLRE_ON & _PWRTE_OFF & _LPBOREN_OFF & _BOREN_ON & _BORV_LO & _ZCD_OFF & _PPS1WAY_OFF & _STVREN_ON & _DEBUG_OFF

__config _CONFIG3, _WDTCPS_WDTCPS_11 & _WDTE_OFF & _WDTCWS_WDTCWS_7 & _WDTCCS_LFINTOSC

__config _CONFIG4, _WRT_OFF & _SCANE_available & _LVP_OFF

__config _CONFIG5, _CP_OFF & _CPD_OFF

#ENDCONFIG

DEFINE OSC 32

DEFINE ADC_BITS 10 ' 10-bit Analog to digital

DEFINE ADC_SAMPLEUS 5 ' Set sampling time in uS

DEFINE HSER_RXREG PORTC

DEFINE HSER_RXBIT 7

DEFINE HSER_TXREG PORTC

DEFINE HSER_TXBIT 6

DEFINE HSER_RCSTA 90h ' Enable serial port & continuous receive

DEFINE HSER_TXSTA 24h ' Enable transmit, BRGH = 1

Define HSER_BAUD 115200

DEFINE HSER_CLROERR 1 ' Clear overflow automatically

DEFINE HSER_SPBRGH 0

DEFINE HSER_SPBRG 68

;--- Setup registers -----------------------------------------------------------

BAUDCON.3 = 1 ' Enable 16 bit baudrate generator

FVRCON = %0000000 ' FIXED VOLTAGE REFERENCE CONTROL REGISTER

ADCON0 = %10000100 ' ADC CONTROL REGISTER 0

' bit 7 ADON: ADC Enable bit

' 1 = ADC is enabled

' bit 2 ADFRM0: ADC results Format/alignment Selection

' 1 = ADRES and ADPREV data are right-justified

ADCON2 = %00000000 ' ADC CONTROL REGISTER 2

' bit 2-0 ADMD<2:0>: ADC Operating Mode Selection bits(1)

' 000 = Basic (Legacy) mode

ADCLK = %00001111 ' ADC CLOCK SELECTION REGISTER

' bit 5-0 ADCCS<5:0>: ADC Conversion Clock Select bits

' 1111 = FOSC/32

ADREF = %00010000 ' ADC REFERENCE SELECTION REGISTER

' bit 4 ADNREF: ADC Negative Voltage Reference Selection bit

' 1 = VREF- is connected to VREF- pin

' 0 = VREF- is connected to AVSS

' bit 1-0 ADPREF: ADC Positive Voltage Reference Selection bits

' 11 = VREF+ is connected to FVR_buffer 1

' 10 = VREF+ is connected to VREF+ pin

' 00 = VREF+ is connected to VDD

WPUA = %11110011

WPUB = %11111111

WPUC = %00111111

ANSELA = %00010111 ' Pin A4 = ADC (B10K) ... not implemented

' Pin A3 = SW input 3

' Pin A2 = Vref-

' Pin A1 = ADC (B5K w/SW)

' Pin A0 = ADC (B5K)

ANSELB = %00000000

ANSELC = %00000000

TRISA = %00011111 ' Pin A4 = ... not implemented

' Pin A3 = ... not implemented

' Pin A2 = Vref-

' Pin A0 = ADC input 0

TRISB = %00000000 ' Pin B7 = ...not available, ICSPDAT

' Pin B6 = ...not available, ICSPCLK

TRISC = %11000000 ' Pin C7 = RX *** Datasheet requirement, INPUT ***

' Pin C6 = TX *** Datasheet requirement, INPUT ***

SW var PORTA.3 ' ... not implemented

MsgData var byte[3]

MsgCode VAR BYTE

ADCinput var WORD

ADCcalc var WORD

ADCdiff var WORD

OldADC var WORD

OldADC0 var WORD

OldADC1 var WORD

Pause 1500 ' Let PIC and LCD stabilize

OldADC0 = 9999

goto Mainloop

;--- Subroutines ---------------------------------------------------------------

SendData:

MsgData[0] = MsgCode : MsgData[1] = ADCcalc.byte1 : MsgData[2] = ADCcalc.byte0

hserout [ MsgData[0], MsgData[1], MsgData[2] ]

while TX1STA.1 = 0 ' Check TRMT bit

wend

oldADC0 = ADCcalc

RETURN

Mainloop:

rem ADC A0 test

MsgCode = 0 ' Record type

adcin 0, ADCinput

ADCcalc = ADCinput >> 2

if ADCcalc < oldADC0 then

ADCdiff = oldADC0 - ADCcalc

else

ADCdiff = ADCcalc - oldADC0

endif

IF ADCdiff > 2 then ' Check for Diff over 2

if ADCcalc <> oldADC0 then ' ADC value changed

GOSUB SendData

endif

ELSE

IF ADCdiff > 0 then ' Check for Diff over 0

if ADCcalc = 0 then ' Reached end of rotation

GOSUB SendData

ELSE

if ADCcalc = 255 then ' Reached end of rotation

GOSUB SendData

endif

endif

endif

endif

GOTO Mainloop

end

I've added banks of caps on the wiper-to-VSS, as well as just before the VDD pin to the pot (0.1uF, 0.01uF and 0.001uF).

I shift right only 2 digits and that seems to have stabilized things quite a lot; no noticeable jitter so far tonight. 256 seems like a workable range for me so far.

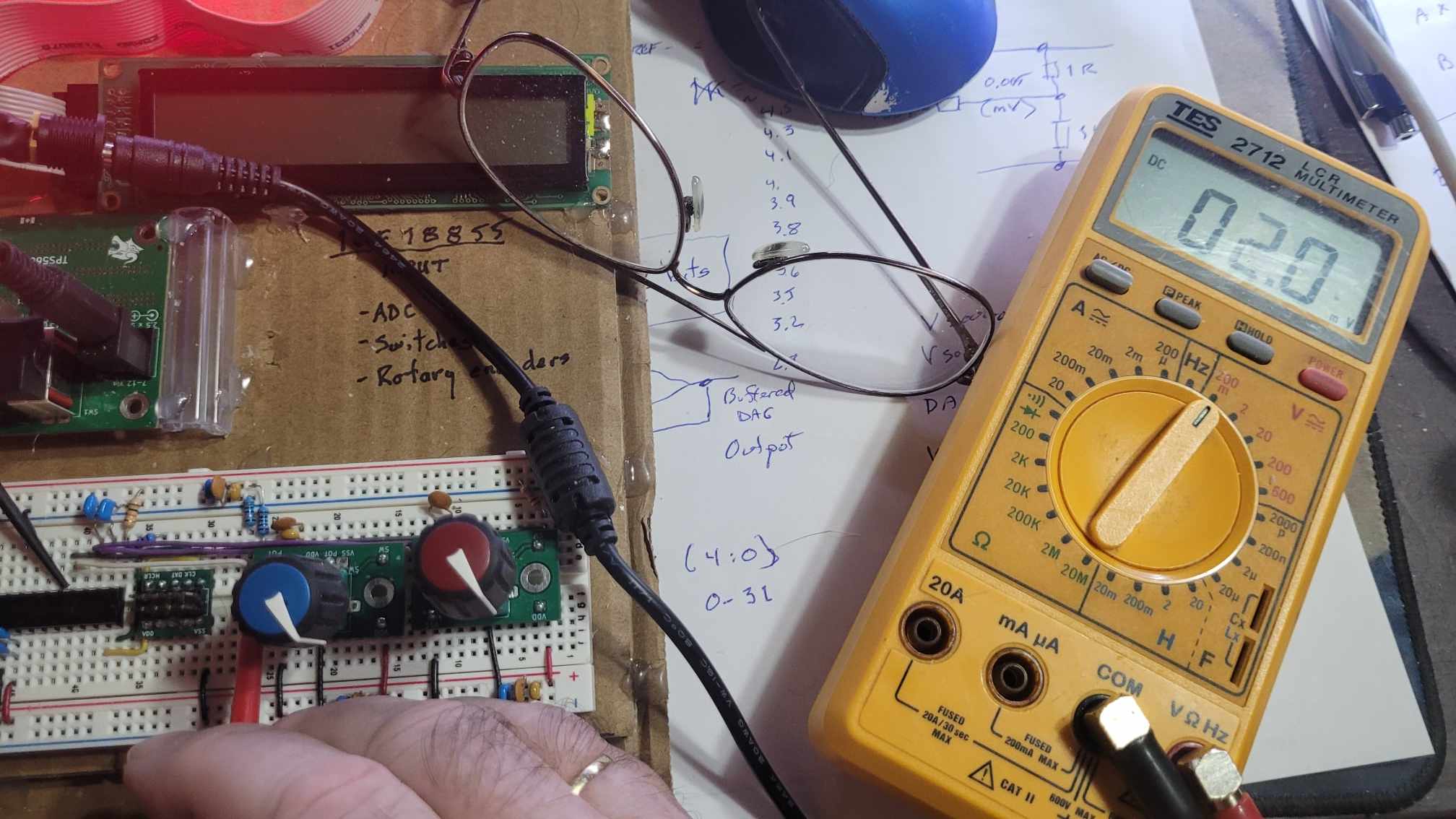

The pot has a reading of 2.0mV when full right:

The Vref- pin reads at 15.7mV (used voltage divider 1K (0.985R really) / 3R:

Pot 0 does not go below ADC=12,and is transmitted on the Saleae probe:

And shows up nicely on LCD on 2nd PIC:

I don't get it. I thought setting Vref- at 15.7mV meant that anything reading below that would read as 0...? I thought I was essentially raising the VSS lower range for ADC.

Code:

ADREF = %00010000 ' ADC REFERENCE SELECTION REGISTER

' bit 4 ADNREF: ADC Negative Voltage Reference Selection bit

' 1 = VREF- is connected to VREF- pin

' 0 = VREF- is connected to AVSS

I'm obviously missing something stupid again, but I don't see what. Or I totally misunderstood what Vref- does in life.

Reply With Quote

Reply With Quote

Bookmarks