Well I finished up the machine and delivered it. My client is thrilled and has more automated machines he wants me to get started on. But like I said I'd post a little about this project. This machine is for a very progressive framing company that is automating every aspect of their business. This machine will except window and door water proofing seal from 4" to 30" wide and interface with their software over USB. They have an in house software engineer that writes all their custom software to break a job down and minimize waist. Every aspect of their framing is maximized through automation. I worked with him over the internet interfacing my control with his software and after a handful of emails and a couple calls we had it debugged and running. Minus my original post here which was a late night, frustration and a wrong configuration bit.It bites us all at some point. So here is the youtube video of the project in front of my shop.

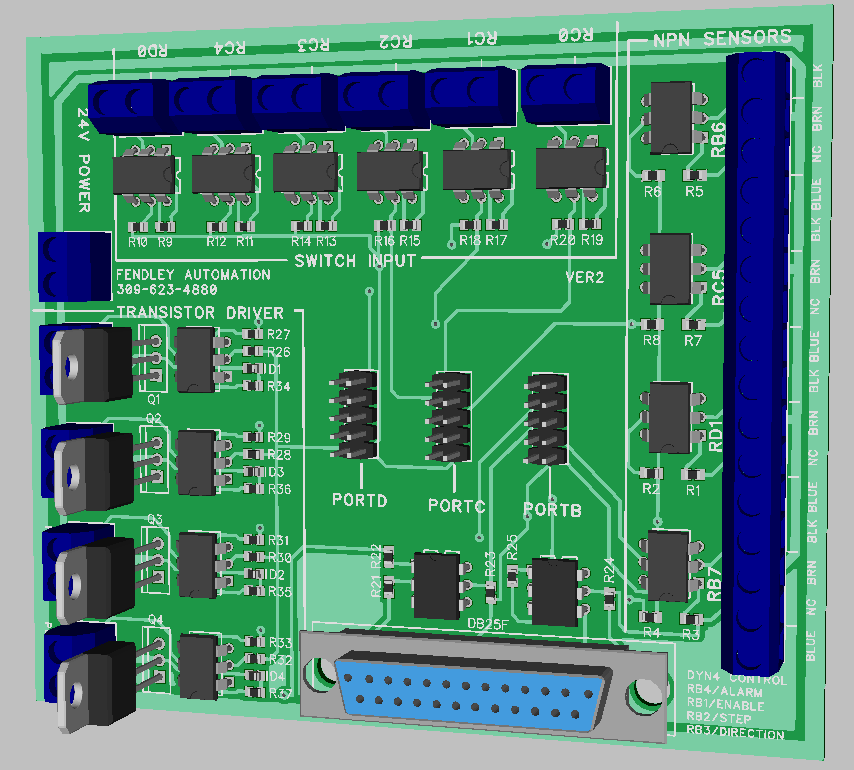

Also the main PCB and secondary interface PCB for using the DYN4 AC servo drive and all inputs and outputs. I'm using a pic18f4431 on the main board because it's a handy controller with and easy to use quadrature encoder. It's one of my basic boards I always use designed in diptrace. Here are some pictures.

Bookmarks