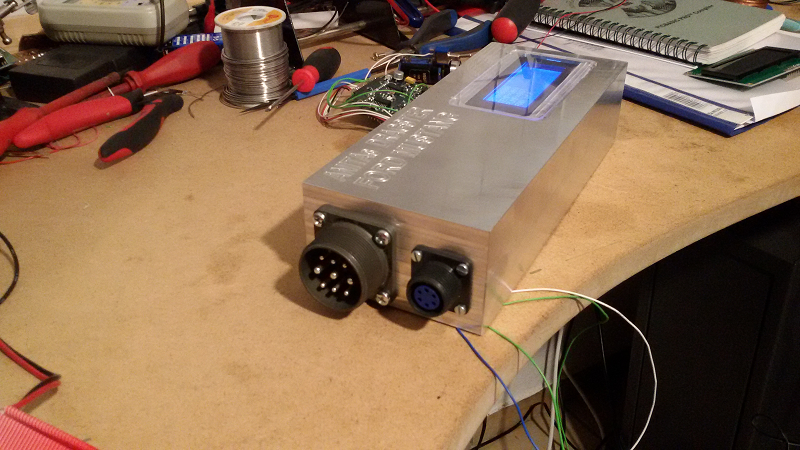

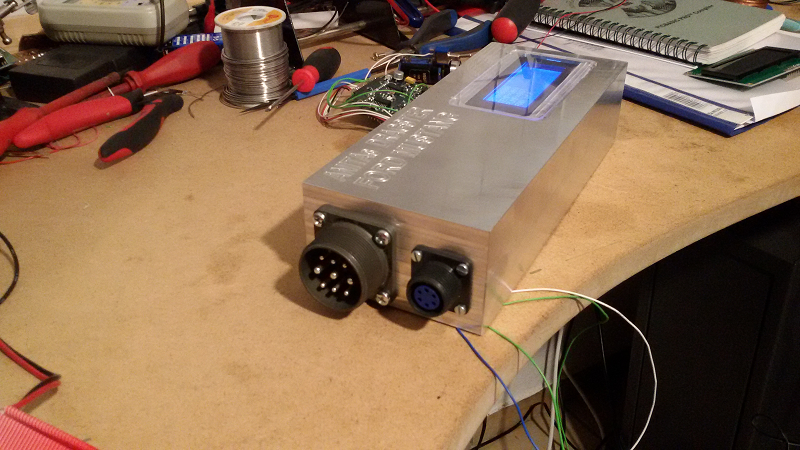

Here three pics of that housing and so on:

Here three pics of that housing and so on:

Mugelpower, I would also like to help so, if you could please explain the whole project overview. Contact me directly via, [email protected] or private email to this site. I have designed N.O.S. controllers for Bracket racers and timing equipment for National Drag Boat Association here in the US. I'm getting ready to retire from current job and need something to do with my spare time...... Been working with PBP for 20+ years.... BTW, I like the Billet housing...

Dave Purola,

N8NTA

EN82fn

If that's the complete code for the '88 it does not seem to be the culprit after all....

The message being sent is 12 bytes, that's 6.35ms @19200 baud, then you have 500us pacing so that's Another 5.5ms for a total of around 12ms. There's nothing else in there that should be taking any considerable amount of time.

Do you have a scope? Can you verify the speed at which the '88 is actually sending messages? It looks like it should be in region of 80Hz...

/Henrik.

Hello Henrik,

i used a scope and found out that the 16F88 program runs with about 60Hz.

So the 18F1320 doesn´t have to wait too long.

The 18F1320 program runs much slower. If I count only 50ms it runs 16Hz. with 100ms it runs 8Hz thats too slow.

50ms count is too short to count while cranking.

So i set it up to 75ms.

The 18F1320 program now runs at 11 Hz. So I call it a day.

I guess the LCD routines gobble up much time.

I put in some IF-THEN commands that showed hardly any effect in slowing down.

I´ll try modifiing "DEFINE LCD_COMMANDUS 1500 "

maybe that can speed things up a little bit.

So, now you're saying it does - sort of - work? No more 300ms delays?

Regarding the LCD: You can try tweaking the default 1500us setting but it's highly dependant on the specific LCD module you're using.

I suspect most of what's on the LCD is static text. If that's true you might gain a fair bit of time (and a much better appearance on the LCD) by just updating the part of the LCD that's actually changing.

Hello Henrik,

I set the baud rate to 38400, that helped a bit.

Then tried set the LCD_COMMANDUS to 1500 that gained hardly anything but made the LCD a bit unreliable.

The count time is down to 75, 50 is loo little, i get no signal when cranking,100 slows the routine cycle down to 8Hz.

Now I got the frequency of a complete routine up to 11.5 Hz.

I guess that should do.

Now I´m back into hardware, soldering and juggling tools, after that testing with real electric motors.

Noise suppression is a real challenge in car electric.

I appreciate your help and the help of all of you folks.

Bookmarks