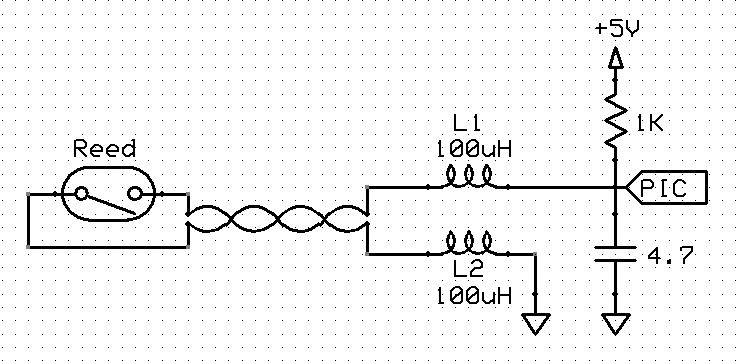

Like the guys said, a stiff pullup and a cap. I would also add an inductor to keep the noise spikes out.

You can probably get by without L2 in this diagram but added it in just in case.

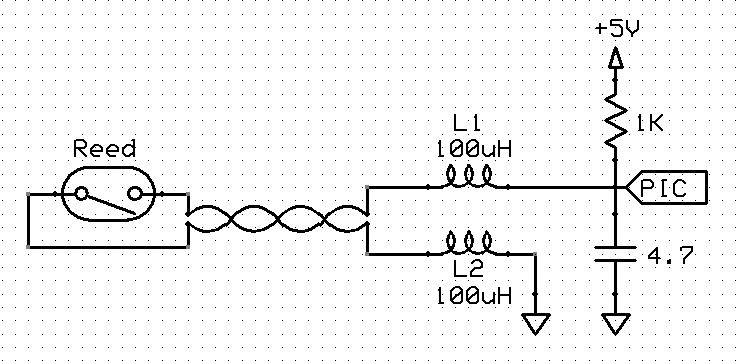

Like the guys said, a stiff pullup and a cap. I would also add an inductor to keep the noise spikes out.

You can probably get by without L2 in this diagram but added it in just in case.

Louie

Bookmarks