Re: 3D printer

Re: 3D printer

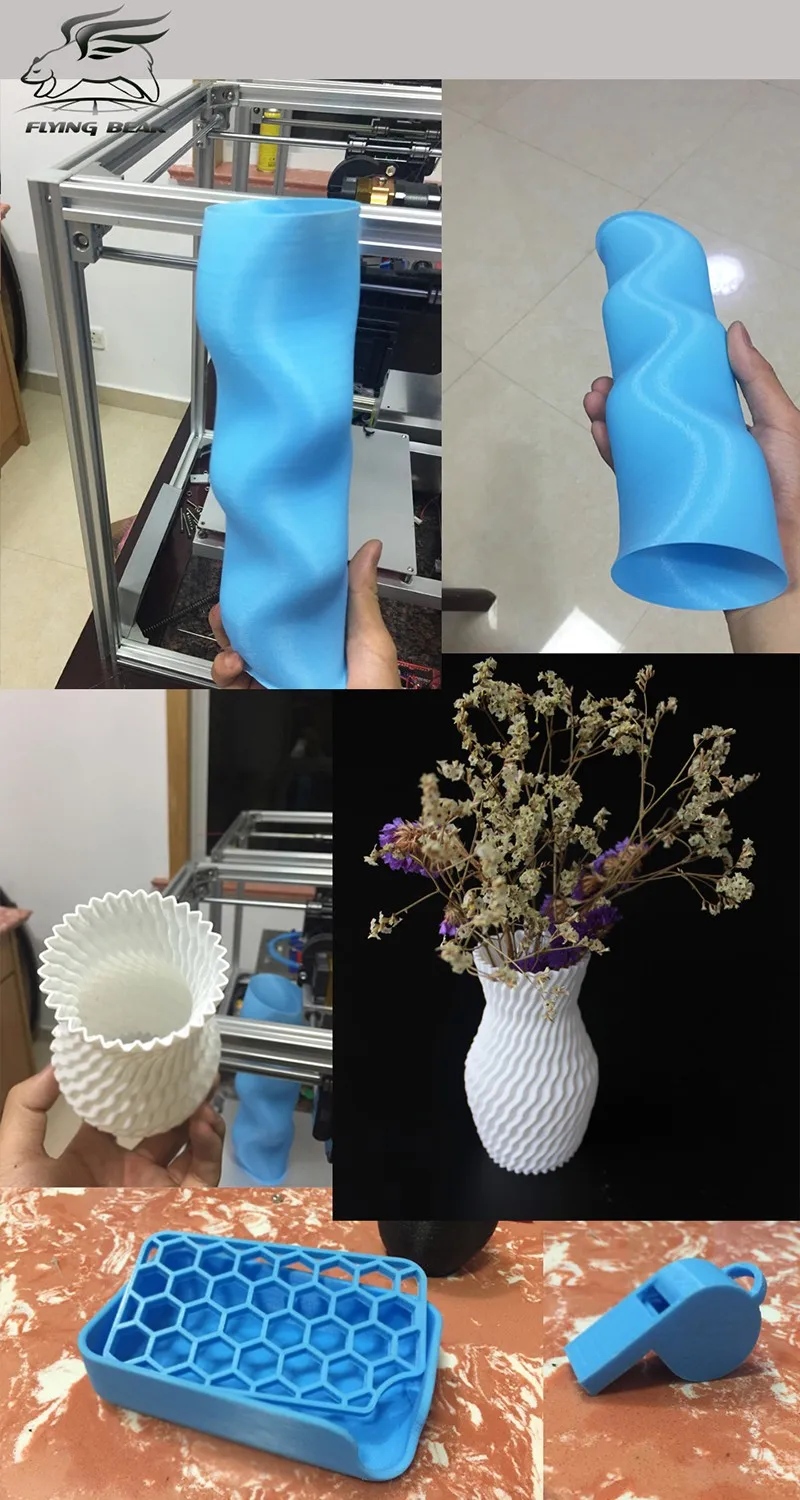

I've had this one for a few months now - very happy with it. The resolution is .2mm though (actually .1984mm) and I think you are looking at pretty heavy cash for ACCURATE .1mm resolution. Lots claim it, its hard to do.

I have modified mine to have a heated bed and have come up with some cool things to get parts that are straight.

I use OpenSCAD for design (its free) - but its another programming language to learn. It took a while, but I'm getting better at it.

Andy

"I have noticed that even those who assert that everything is predestined and that

we can change nothing about it still look both ways before they cross the street"

-Stephen Hawking

Bookmarks