Re: Stable ADC readings

Re: Stable ADC readings

Hervé, je veux bien t'aider du mieux que je peut, mais tu va devoir faire une partie des devoirs de ton coté.

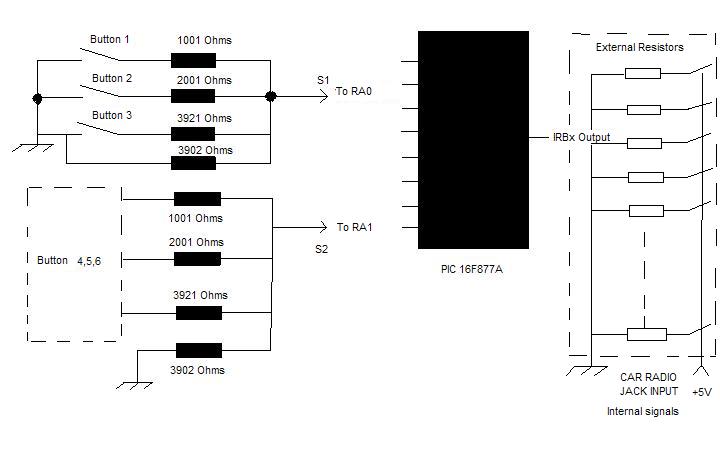

Ok, let's observe the schematic you posted

OK, please answer the following question:

Q1: The Resistor attached to the button are built-in the remote/Steering and you can't modify anything in right?

A1:_______________________________________

Q2: You have a 10K pull-up On RA0, and another on RA1... true?

A2:________________________________________

Q3: If so, assuming you don't push on any button, Between GND and RA0 AND between GND and RA1 with your multimeter you should read something like 1.4Volt RIGHT?

A3:________________________________________

From there, we need to etablish at least 4 conditions

1) ADC reading when no push button are pressed

2) ADC Reading when you push on Button 1 alone

3) ADC Reading when you push on Button 2 alone

4) ADC Reading when you push on Button 3 alone

We can use maths to do so OR output each ADC reading to a LCD OR send the data do your PC via serial communication OR store them in the PIC EEPROM. Choice is yours. Let's see if the maths could work here.

Without any push button pressed, I said around 1.4. Using the voltage divider theory

(3902/(3902+10000))*5 = 1.403

so the ADC should return something like

(1.4/5)*1023 = 287

Do the same with the other resistor value and you should be able to evaluate

1) when no push button are pressed

V = 1.4

ADC Reading = 287

2) When you push on Button 1 alone

V = 0.37

ADC Reading = 76

3) When you push on Button 2 alone

V = 0.58

ADC Reading = 119

4) When you push on Button 3 alone

V = 0.82

ADC Reading = 168

Now, try this.

Code:

'

' Hardware setup

' ==============

'

' I/O

' ---

TRISA = %00000011 ' RA0 et RA1 en entrée

TRISB = 255 ' Disconnect all resistor from the circuit

PORTB = 0 '

'

' ADC

' ---

DEFINE ADC_BITS 10 ' Set number of bits in result

DEFINE ADC_CLOCK 3 ' Set clock source (rc = 3)

DEFINE ADC_SAMPLEUS 50 ' Set sampling time in

ADCON1 = %10000010 ' RA0 à RA3

'

' Software Variable

' =================

ADRes VAR WORD ' ADC Reading

BTN var byte ' Data to be sent to PORTB

i VAR BYTE '

ADCChannel VAR BIT '

ADCButton VAR BYTE [3]'

'

' Software constant

' =================

ADCSafety CON 10 ' min/max range for ADC Reading

'

ADCNone CON 287 - ADCSafety '

ADCButton[0] = 76 ' button 1 or 4

ADCButton[1] = 119 ' button 2 or 5

ADCButton[2] = 168 ' button 3 or 6

Start:

TRISB = 255 ' Disconnect all resistor from the circuit

ADCIN ADCChannel,ADRes ' Read ADC

'

if (ADRes < ADCNone) Then ' Any button down?!?

' - Yes!

FOR i = 2 TO 0 STEP -1 ' Loop through all 3 calculated posibilities

' Test against calculated ADCresult

' and allow a range of +/- ADCSafety

IF (ADRes > (ADCButton[i]-ADCSafety)) AND (ADRes < (ADCButton[i]+ADCSafety)) THEN

' Valid ADC result, clear the coresponding I/O

TRISB = ((DCD i) << (ADCChannel*3)) ^255

PAUSE 200

i=0 ' and getOut of here

ENDIF '

'

NEXT '

'

else ' - NO!

' Switch to the other ADC channel

ADCChannel = ADCChannel ^ 1

ENDIF

GOTO Start '

Button 1, enable PORTB.0, Button 2 PORTB.1 etc etc.

For testing purpose use LEDs to VDD. It works here.

Steve

It's not a bug, it's a random feature.

There's no problem, only learning opportunities.

Bookmarks