It would be nice if this config fuse tool could parse the xxx.inc file, and post these options for you. That way, as new chips are given, the new .inc file inputs the data, without manual input. It is all here.

Code:

; Configuration Bits

;

; NAME Address

; CONFIG1H 300001h

; CONFIG2L 300002h

; CONFIG2H 300003h

; CONFIG3L 300004h

; CONFIG3H 300005h

; CONFIG4L 300006h

; CONFIG5L 300008h

; CONFIG5H 300009h

; CONFIG6L 30000Ah

; CONFIG6H 30000Bh

; CONFIG7L 30000Ch

; CONFIG7H 30000Dh

;

;==========================================================================

; The following is an assignment of address values for all of the

; configuration registers for the purpose of table reads

_CONFIG1H EQU H'300001'

_CONFIG2L EQU H'300002'

_CONFIG2H EQU H'300003'

_CONFIG3L EQU H'300004'

_CONFIG3H EQU H'300005'

_CONFIG4L EQU H'300006'

_CONFIG5L EQU H'300008'

_CONFIG5H EQU H'300009'

_CONFIG6L EQU H'30000A'

_CONFIG6H EQU H'30000B'

_CONFIG7L EQU H'30000C'

_CONFIG7H EQU H'30000D'

;----- CONFIG1H Options --------------------------------------------------

_OSC_LP_1H EQU H'F0' ; LP

_OSC_XT_1H EQU H'F1' ; XT

_OSC_HS_1H EQU H'F2' ; HS

_OSC_RC2_1H EQU H'F3' ; External RC, RA6 is CLKOUT

_OSC_EC_1H EQU H'F4' ; EC, RA6 is CLKOUT

_OSC_ECIO_1H EQU H'F5' ; EC, RA6 is I/O

_OSC_HSPLL_1H EQU H'F6' ; HS-PLL Enabled

_OSC_RCIO_1H EQU H'F7' ; External RC, RA6 is I/O

_OSC_IRCIO_1H EQU H'F8' ; Internal RC, RA6 & RA7 are I/O

_OSC_IRC_1H EQU H'F9' ; Internal RC, RA6 is CLKOUT, RA7 is I/O

_OSC_RC1_1H EQU H'FB' ; External RC, RA6 is CLKOUT

_OSC_RC_1H EQU H'FF' ; External RC, RA6 is CLKOUT

_FCMEN_OFF_1H EQU H'BF' ; Disabled

_FCMEN_ON_1H EQU H'FF' ; Enabled

_IESO_OFF_1H EQU H'7F' ; Disabled

_IESO_ON_1H EQU H'FF' ; Enabled

;----- CONFIG2L Options --------------------------------------------------

_PWRTEN_ON_2L EQU H'FE' ; Enabled

_PWRTEN_OFF_2L EQU H'FF' ; Disabled

_BOREN_OFF_2L EQU H'FD' ; Disabled

_BOREN_ON_2L EQU H'FF' ; Enabled

_BORV_45_2L EQU H'F3' ; 4.5V

_BORV_42_2L EQU H'F7' ; 4.2V

_BORV_27_2L EQU H'FB' ; 2.7V

_BORV_20_2L EQU H'FF' ; 2.0V

;----- CONFIG2H Options --------------------------------------------------

_WDTEN_OFF_2H EQU H'FE' ; Disabled

_WDTEN_ON_2H EQU H'FF' ; Enabled

_WINEN_ON_2H EQU H'DF' ; Enabled

_WINEN_OFF_2H EQU H'FF' ; Disabled

_WDPS_1_2H EQU H'E1' ; 1:1

_WDPS_2_2H EQU H'E3' ; 1:2

_WDPS_4_2H EQU H'E5' ; 1:4

_WDPS_8_2H EQU H'E7' ; 1:8

_WDPS_16_2H EQU H'E9' ; 1:16

_WDPS_32_2H EQU H'EB' ; 1:32

_WDPS_64_2H EQU H'ED' ; 1:64

_WDPS_128_2H EQU H'EF' ; 1:128

_WDPS_256_2H EQU H'F1' ; 1:256

_WDPS_512_2H EQU H'F3' ; 1:512

_WDPS_1024_2H EQU H'F5' ; 1:1024

_WDPS_2048_2H EQU H'F7' ; 1:2048

_WDPS_4096_2H EQU H'F9' ; 1:4096

_WDPS_8192_2H EQU H'FB' ; 1:8192

_WDPS_16384_2H EQU H'FD' ; 1:16384

_WDPS_32768_2H EQU H'FF' ; 1:32768

;----- CONFIG3L Options --------------------------------------------------

_T1OSCMX_OFF_3L EQU H'DF' ; Active

_T1OSCMX_ON_3L EQU H'FF' ; Inactive

_HPOL_LOW_3L EQU H'EF' ; Active low

_HPOL_HIGH_3L EQU H'FF' ; Active high

_LPOL_LOW_3L EQU H'F7' ; Active low

_LPOL_HIGH_3L EQU H'FF' ; Active high

_PWMPIN_ON_3L EQU H'FB' ; Enabled

_PWMPIN_OFF_3L EQU H'FF' ; Disabled

;----- CONFIG3H Options --------------------------------------------------

_MCLRE_OFF_3H EQU H'7F' ; Disabled

_MCLRE_ON_3H EQU H'FF' ; Enabled

;----- CONFIG4L Options --------------------------------------------------

_STVREN_OFF_4L EQU H'FE' ; Disabled

_STVREN_ON_4L EQU H'FF' ; Enabled

_LVP_OFF_4L EQU H'FB' ; Disabled

_LVP_ON_4L EQU H'FF' ; Enabled

_DEBUG_ON_4L EQU H'7F' ; Enabled

_DEBUG_OFF_4L EQU H'FF' ; Disabled

;----- CONFIG5L Options --------------------------------------------------

_CP0_ON_5L EQU H'FE' ; Enabled

_CP0_OFF_5L EQU H'FF' ; Disabled

_CP1_ON_5L EQU H'FD' ; Enabled

_CP1_OFF_5L EQU H'FF' ; Disabled

_CP2_ON_5L EQU H'FB' ; Enabled

_CP2_OFF_5L EQU H'FF' ; Disabled

_CP3_ON_5L EQU H'F7' ; Enabled

_CP3_OFF_5L EQU H'FF' ; Disabled

;----- CONFIG5H Options --------------------------------------------------

_CPB_ON_5H EQU H'BF' ; Enabled

_CPB_OFF_5H EQU H'FF' ; Disabled

_CPD_ON_5H EQU H'7F' ; Enabled

_CPD_OFF_5H EQU H'FF' ; Disabled

;----- CONFIG6L Options --------------------------------------------------

_WRT0_ON_6L EQU H'FE' ; Enabled

_WRT0_OFF_6L EQU H'FF' ; Disabled

_WRT1_ON_6L EQU H'FD' ; Enabled

_WRT1_OFF_6L EQU H'FF' ; Disabled

;----- CONFIG6H Options --------------------------------------------------

_WRTB_ON_6H EQU H'BF' ; Enabled

_WRTB_OFF_6H EQU H'FF' ; Disabled

_WRTC_ON_6H EQU H'DF' ; Enabled

_WRTC_OFF_6H EQU H'FF' ; Disabled

_WRTD_ON_6H EQU H'7F' ; Enabled

_WRTD_OFF_6H EQU H'FF' ; Disabled

;----- CONFIG7L Options --------------------------------------------------

_EBTR0_ON_7L EQU H'FE' ; Enabled

_EBTR0_OFF_7L EQU H'FF' ; Disabled

_EBTR1_ON_7L EQU H'FD' ; Enabled

_EBTR1_OFF_7L EQU H'FF' ; Disabled

;----- CONFIG7H Options --------------------------------------------------

_EBTRB_ON_7H EQU H'BF' ; Enabled

_EBTRB_OFF_7H EQU H'FF' ; Disabled

_DEVID1 EQU H'3FFFFE'

_DEVID2 EQU H'3FFFFF'

_IDLOC0 EQU H'200000'

_IDLOC1 EQU H'200001'

_IDLOC2 EQU H'200002'

_IDLOC3 EQU H'200003'

_IDLOC4 EQU H'200004'

_IDLOC5 EQU H'200005'

_IDLOC6 EQU H'200006'

_IDLOC7 EQU H'200007'

It would even be a start to be able to click on your selections, and have it bring up relevant code for both including in your code, or for adding to your PBP inc file.

like:

Code:

asm

__CONFIG _CONFIG1H, _OSC_HSPLL_1H

__CONFIG _CONFIG2H, _WDTEN_OFF_2H & _WDPS_512_2H

__CONFIG _CONFIG4L, _LVP_OFF_4L

endasm

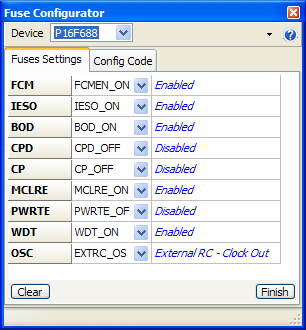

It looks like Proton has a simple config "tool" here:

http://wiki.picbasic.org/index.php?n...seConfigurator

CCS just shows you the configs, like this:

It would be nice to expand on it, and make it easier. I think everyone has gotten stuck with configs. I know I sure have.

With a quick look around the net, I can't find any manufacturer or software maker that has made this very easy for any chip. You would think Microchip would be interested in this, as it would really give them an edge. Perhaps you can sell it to them when you are done!

tell you you could have an eye on the MikroE Edit Project Window ...

tell you you could have an eye on the MikroE Edit Project Window ...

Bookmarks