Is this the way to get negative reading? i am new to this, so sorry if i mixed it up.

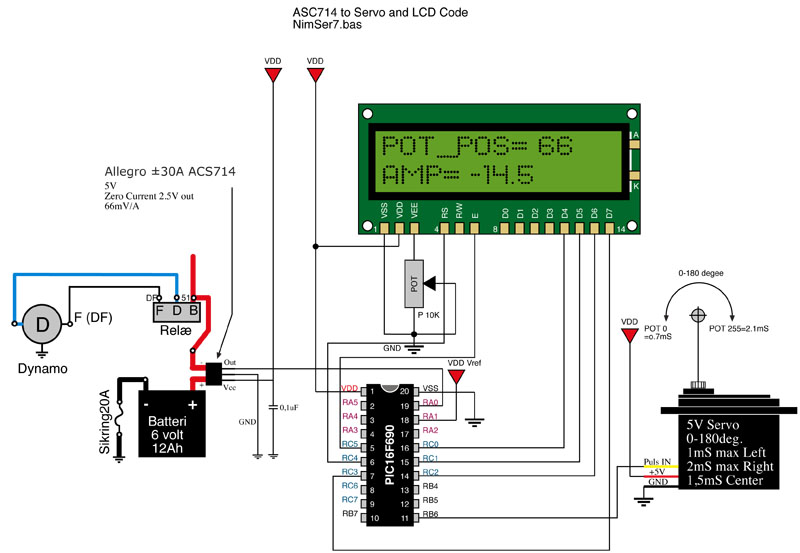

I use Allegro ACS714 but with a PIF16F690 with A/D set to 8bit, should not be any difference.

It works and can read +30Amp to -30Amp.

The problem is that i use 0V and 5V as reference. I cant figure out to get 0.52V to read 0 and 4.48V to read 255? Is it a math problem or must i add an external ref?

The ACS gives 66mV/A:

Amp Vin Bit

+30A 4.480 255

+10A 3.160

+1A 2.566

0A 2.500 127

-1A 2,434

-10A 1.840

-30A 0.520 0

See CODE below and attached DRAWING

Code:

'Define OSC and ADC

DEFINE OSC 4 ' Set internal Oschillator to 4Mhz

DEFINE ADC_BITS 8 ' Set number of bits in result

DEFINE ADC_CLOCK 2 ' Set clock source (3=rc)

DEFINE ADC_SAMPLEUS 50 ' Set sampling time in uS

' Define LCD pins

Define LCD_DREG PORTC 'LCD data port

Define LCD_DBIT 0 'LCD data starting bit 0 or 4

Define LCD_RSREG PORTC 'LCD register select port

Define LCD_RSBIT 4 'LCD register select bit

Define LCD_EREG PORTC 'LCD enable port

Define LCD_EBIT 5 'LCD enable bit

TRISA = %00001001 ' RA0 = A/D input

ADCON1.7 = 0 ' RA.1 = +Vref, Set PORTA analog and left justify result

PORTb.6 =0 ' Prepare RB0 for high-going pulseout

ANSEL = %00000101 ' Set PORTA.2 analog, rest digital

ANSELH = %00000000

' Variables

outpuls VAR WORD ' Variable for the calculated puls out in mS

POT_POS VAR BYTE ' Potentiometer position CC=0, CCW=255

amp var word ' Ampere 30A-0-30A (0-127-255)

Pause 500 ' Wait for LCD to start

MainLoop: ' The Loop start here!

ADCIN 0,POT_POS ' Read A/D channel 0 to variable SVO_POS

'Check if negative or positive Ampere

IF POT_POS=>127 then

amp=(235 * (POT_POS-127))

else

amp=(235 * (128-POT_POS))

endif

Lcdout $fe, 1, "POT_POS= ", #POT_POS ' Display POT Valu between 0-255 on line 1

' Check if negtive or positive Ampere, only for - minus sign on LCD display

IF POT_POS=>127 then

LCDOut $fe,$C0, "AMP= ",DEC (amp/1000),".", DEC1 amp' Display +Amp on line 2

else

LCDOut $fe,$C0, "AMP= -",DEC (amp/1000),".", DEC1 amp' Display -Amp on line 2

endif

PAUSE 20 ' Constant 20mS pulses(low) between outpuls

GOTO MainLoop ' Forever

End

.

.

Bookmarks