My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

You just need less than 2.2 volts at the input for the HC14 to interpret it as low. So, yes, either 100k/10k or 10k/1k combination is OK. Better 100k/10k though, because it will draw much less current.

Ioannis

Last edited by Ioannis; - 14th January 2024 at 19:18.

How many buttons will be pressed at the same time?

Maybe state machine is another good solution for such a project. I can dig out an example for small amount of buttons that I am sure can be expanded for more. the advantage is that no pause is used because it is out of the state machine philosophy of operation.

Ioannis

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

In theory, only one button gets pressed at a time.

It's essentially a button box; something like this:

https://i.ebayimg.com/images/g/AX0AA...D1/s-l1600.jpg

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Maybe then it is worth to try this:

100 buttons means about 13 bytes.

You can read that 13 bytes, store them in a temp array.

Do whatever you want and a timer interrupt will get you back to read again the 13 bytes in about 10ms or whatever you want.

Compare to the previous read in temp array. If there is a difference, you can jump to the appropriate sub using ON index GOTO or BRANCHL technique, for up to 127 or 1024 labels to goto.

No pauses, no delays to the main program. An no 200 resistors and 100 capacitors along with a bunch of HC14's.

Ioannis

Last edited by Ioannis; - 14th January 2024 at 22:14.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

i agree with ioannis ,all that extra hardware will not add much value [if any] when you need to keep track off switch states anyway

getting multiple re's to work glitch free when other interrupts are involved is very challengingI also have several rotary encoders. You can spin those around quite fast

these things work great and are open sourced or you can buy some

https://www.tindie.com/products/saim...er-on-i2c-bus/

Warning I'm not a teacher

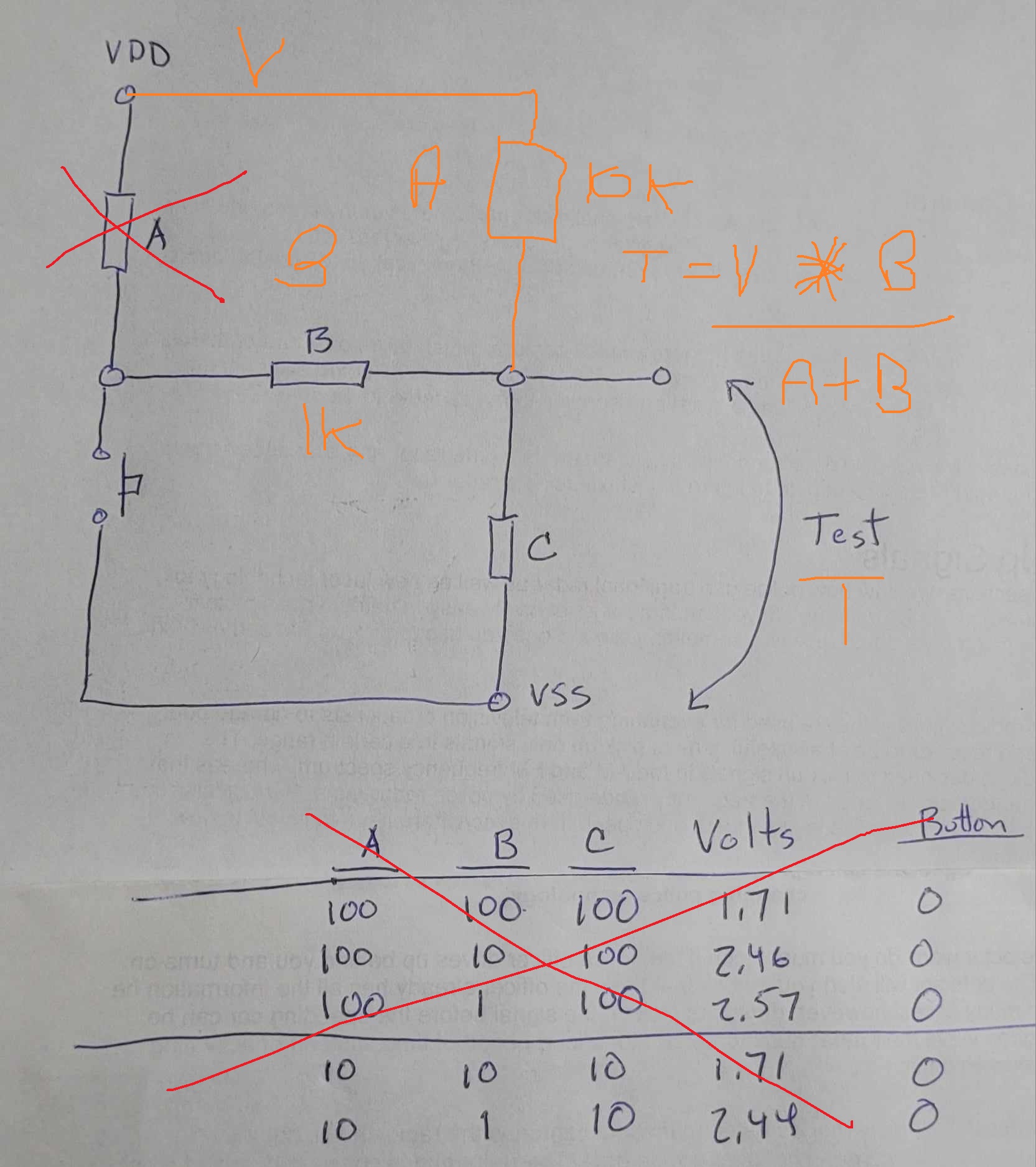

I can't do math since I can't remember squat. It's faster for me to pull out the breadboard and test it out. This is what I got:

(corrected cause I'm senile)

And this is the specs for the 74HC14 that I'm using:

It looks like I'm better off using 100K-1K-100K or 10K-1K-10K to be sure to be in 2.5V range. I didn't check current consumption.

I suppose the dude on that link used the 74HCT14 (at the bottom of specs). The positive-going threshold is about 1.5V, depending on VCC.

Last edited by Demon; - 15th January 2024 at 03:23.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Now you're talking. I don't need all that RGB stuff, just rotary encoder with switch support is all I need.

https://www.tindie.com/products/saim...-encoder-mini/

I ordered 20 of the mini model to test, $2.28USD, turns out to $74.79CAD with normal shipping and exchange rate.

Real interesting stuff. If everything is there to be open-source, I could even print my own.

Last edited by Demon; - 15th January 2024 at 03:33.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

you sketch is incorrect , with button pressed v test == 0.45 v

Warning I'm not a teacher

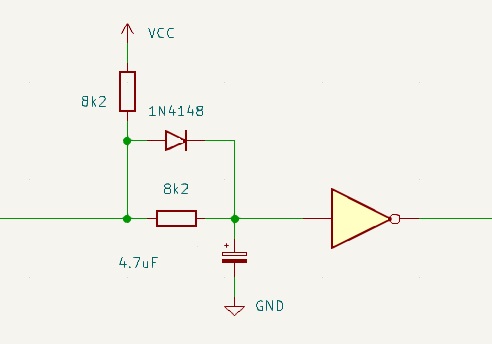

I used this guys design.

https://hackaday.com/wp-content/uplo...uncing-sch.png

His explanation is here:

https://hackaday.com/2015/12/09/embe...uttons-part-i/

I've seen this design in other places. The 3rd resistor is to prevent the input pin from floating.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

i see , you need to know the leakage current from the ST gate input to calculate the voltages . after the rc time constant is allowed for of course

seems messy to me , at 100k the button may never work depending on ST characteristics

Warning I'm not a teacher

Oooops. I've since added a pull-down for the input I was using.

I'm seeing several comments on google about connecting the unused pins to ground. If I'm not using their output, can a floating input disturb the other circuits?

EDIT: I've googled some more and found this explanation:

"...random charges accumulating there can/will cause unpredictable internal behavior in the chip, including oscillation and high power dissipation."

https://electronics.stackexchange.co...-inputs-outpus

Last edited by Demon; - 15th January 2024 at 04:26.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Better be on the safe side. Richards #91 is the one I would use.

But then you can ditch all that stuff if your ports support internal pull up and just read them in software as described in #86.

Ioannis

the pull down resistor is a bad idea, the hackaday article [if you wish to trust it] does not have one and does not suggest one.

biasing cmos inputs to values inbetween logic high and logic low thresholds is a proven method for making oscillators , i would not recommend it as a debounce cct. the input pin in the article is never in a floating state regardless of button state, unused cmos input pins cannot be left to float, a completely different thing

Warning I'm not a teacher

I guess you refer to post #89. There are no pull downs. It was a graphic design error that meant to be a capacitor, as designated by the letter C.

Ioannis

Last edited by Ioannis; - 15th January 2024 at 21:16.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

There's a god discussion on Reddit about JLCPCB.

https://www.reddit.com/r/PCB/comment...than_everyone/

- I remember a time when Made in Japan was a joke, and then they joined the leaders in electronics.

- I remember a time when Korean cars was ridiculed, and now they made products that compare or surpass American models.

- I remember a time when Made in China meant cheap crap that broke easily, and now they are rivaling and even beating some North American PCB fabricators.

We keep sitting on our laurels while the planet passes us. I really want to encourage local businesses, but it's becoming impossible at these prices.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

This cropped up recently on arduino forum as a debounce in noisy [automotive] enviro as an effective debounce method

Warning I'm not a teacher

Yeah, I've saved an article from February 2020 about this one too:

https://www.eejournal.com/article/ul...bounce-part-3/

I had even tried it without success, but I used a breadboard and that most likely caused me a ton of bad connections. This last batch I got from AliExpress leaves a lot to be desired.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

The reason why I'm sticking with the Hackaday design is because the front end is recommended by Bourns with their rotary encoders (page 3).

https://www.bourns.com/docs/Product-...ets/PEC11R.pdf

I figure if they can recommend this design with their products, it's gotta have some merit when you consider how easily liability lawsuits get thrown around in the US.

Unless I'm mistaken, the Elliot Williams design from Hackaday that I'm using is exactly the same, but with the Schmitt Trigger added at the back end.

About that other technique of just storing the state in a bunch of bits, and then checking for a "clean press", Elliot encountered a problem with a "janky button".

https://hackaday.com/2015/12/10/embe...i/#more-180185

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

If a button has serious problem, it has to be replaced.

The usual, normal behavior of a metal contact switch is to bounce a few ms and then settle. That is why a 10ms debounce is most recommended. More may be better if you can spare the time, either in software or hardware.

In your case, with so many buttons, you will be using too many components. All these can be just fine be replaced with a few more lines of code for free. And with less posibility for a component or soldering it ot pcb to fail.

Ioannis

One issue that's been a thorn in my side since day 1 was how to engrave text on the enclosure. One of the easiest ways was to use double-layer ABS engraving sheets like this and engrave text with a mini-CNC or laser:

https://www.amazon.ca/gp/product/B07QT93LN9/

My problem was how to have a nice finish along the edges, cause you can see the white backing. I doubt I could get paint to match, and thin moldings would not go on straight. I finally got a breakthrough today; I print my own 1-piece molding, but with alignment pegs.

In theory I should have a decent enclosure front panel. And best of all, I'm not getting these sheets from Amazon any more, I just got a waaaay better price straight from the manufacturer. And they will cut the sheets to my exact specs, I don't have to trim, so less waste and lower costs.

And even better, the sales rep said they can customize everything about my order. I can get semi-opaque backing of the colour of my choice. I just slap some LEDs in the enclosure behind the text and VOILA! Instant backlighting.

This is such a relief. I didn't want my case to look DIY that much; a professional look helps customer confidence in your product.

Last edited by Demon; - 21st February 2024 at 06:36.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Nice project you have going Demon. I have used this company before at work and have had great results.

Paul

Front Panel Creator - Front Panels

Wow! Those are exactly what I am aiming to get.

Only one question, is that fee just for the designing on Panel Creator, and then a separate fee from Precision Graphics?

I've made contact with a manufacturer in China for something like these, but I haven't sent any models yet for pricing.

Last edited by Demon; - 28th February 2024 at 05:39.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

I just got 2 sample LCDs from a manufacturer. Holy crapenslaque! They're even nicer than my aging Acer displays (22in and 19in at top of pic).

This is FHD 15.6in 1920x1080. It has HDMI and VGA inputs, and runs on ordinary 12V 2A power supply. If you get a USB-display adapter (maybe $25 on amazon), you don't even waste graphic card outputs.

It's freaking awesome, way better than I hoped, viewing angle is super. Way better than the crap I got on aliexpress:

Now I just have to make a case for it.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

That is great! Nice choice.

What enclosure are thinking to make?

Ioannis

That part is still up in the air. My 3D printer only goes to 300mm x 300mm x 300mm, so that's not an option for a 15.6in display.

I might print it in 2 parts, then glue them together to make a prototype, then make a mold using Smooth-On silicon.

That might be my only option at this point.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

At this size, maybe wood is an option for the prototype?

I saw Smooth-On silicon which is very exciting! But for an enclosure too much of work I guess.

Ioannis

I like wood, but it's a bit too bulky for what I had in mind. The prototype has to be thin, or else it's going to cost a lot of liquid plastic to pour each enclosure. I could use other medium, like plexiglass and superglue; that's my backup plan. I'd have relatively thin walls and a smooth surface, with a minimal strength. I'm just not keen on using superglue.

I'm looking at making the prototype on the 3D printer; most likely in 2 parts. That way I can have thin walls but keep a relatively high level of precision in dimensions. The other nice thing, is that modifying and restarting is just a matter of editing in FreeCad. With wood, you have to start again, same with all other "manual medium".

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

I drew up a basic frame, just to get an idea of what I'm facing; 15 hours, and there's no fasteners or anything.

The panel with all the holes was just a temporary support, since I have to print it an at angle on the printer. I'm still missing screws around the perimeter, and braces to hold it at an angle (I make my own, less waste, and they're signed specifically for the print). So I might be facing about 25 hours at regular speed on my printer for a complete front frame.

Then I have to print a honeycomb spacer for rigidity (maybe 10mm thick), and a backside with all the screws and required connector openings. I'm guesstimating at least 50 hours of printing for an enclosure prototype.

And this is why I'm considering a multi-part design. I could print it flat and wouldn't need to print all those supports. I'd have an annoying joint down the center, but I could live with that if I had to.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Whatever you choose for the prototype, it needs a lot of time.

At least with 3D you have freedom to do anything you like.

Keep on!

Ioannis

Like this:

I print 2 of these, rotate one around, and the pin at the bottom end will fit into the slot on the far right end:

Under 5 hours to print a single piece this way, so a total of 10 hours, no waste of supports, the face plate is essentially finished and a lot less time.

I just have to cover that joint with finishing putty, sand, prime, and I should be good to pour a silicone mold over it.

EDIT: Those 2 50-50 holes down the center are bugging me. I'll probably slide the bottom hole over to the left, and shorten the top beam. That way it'll be complete, no loose screw to jiggle about (in case I end up with a bad mold cavity).

Last edited by Demon; - 12th March 2024 at 01:30.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Version 2:

- I made the alignment tab & slot longer, to help the frame glue perfectly straight.

- I only did drill marks for the cover screws. I'm using M3 self-tapping screws, I had problems making molds for small screws in the past. I just have to pass the frames under a dremel drill press to make the complete 2.5mm DIA holes.

That center hole still bugs me. Gonna have to move it over a tad.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

are you printing in pla ?

if so what glue are you using , the only glue i find that works well is that nasty solvent based scigrip 16 [dimethylene chloride ?]

once you crack the seal it quickly dry's up in the tube no matter how diligent you are resealing it and its not cheap. i keep mine in the fridge.

super glue just unsticks and falls off after a few weeks

Warning I'm not a teacher

Can save a bit more time printing both halves at the same time.

I did a test print and quickly noticed something; the frame bends as it cools after being removed from the printer. I'm going to let it cool on its own on the printer next time.

(it's so light, the darn thing kept jiggling)

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Confirmed on tube, ordinary cyano-thingy GH1200 from dollar store.

Broke the frame in two, glued them together. I'm hurting my fingers trying to separate the pieces.

I'm gonna let it on the shelf and see how long it lasts.

Last edited by Demon; - 12th March 2024 at 04:37.

My Creality Ender 3 S1 Plus is a giant paperweight that can't even be used as a boat anchor, cause I'd be fined for polluting our waterways with electronic devices.

Not as dumb as yesterday, but stupider than tomorrow!

Bookmarks