Originally Posted by

Kenjones1935

I want addresses 00 and 01 to look like 4729, or preferably rounded down to 0047 or up to 0048.

This will write asci to your eeprom data. Your PicKit2 can be set to read data as asci with the little drop down box. By the way, I hope you are not writing to the eeprom each time a distance is measured, because you will wear your chip out pretty quick that way.

Code:

distance var word

inches var byte

distance = 700

distance = distance * 10

distance = distance + 74 'add half of divisor (148) , this is not needed, but will "round up" if you want to be a little more accurate

inches = distance / 148

write 0,61 'For "=" (standard asci character set)

'the + 48 changes it from dec to asci

write 1, inches dig 2 + 48 'will be a "0" if inches = 47

write 2, inches dig 1 + 48 'will be a "4" if inches = 47

write 3, inches dig 0 + 48 'will be a "7" if inches = 47

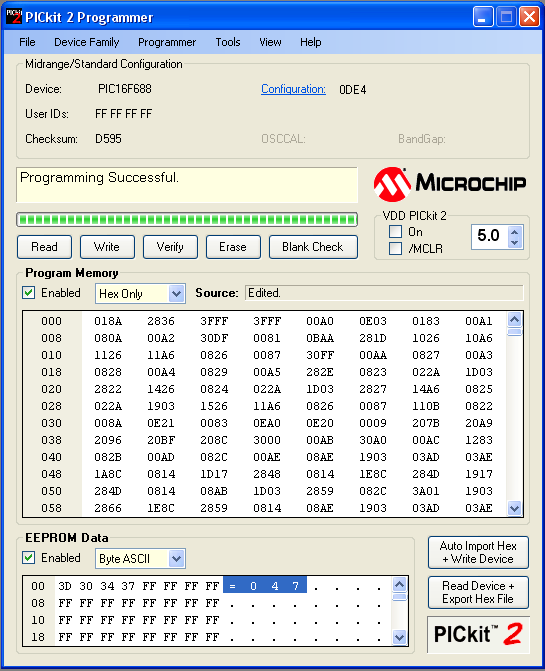

Then you can view it like this:

sinec your result is measured in 10uS steps, according to the spec for your sonar, "If the pulse is measured in uS, then divide by 148 to get inches". So all you have to do is inchesright = rangeright/148. And inchesfront = rangefront/148.

sinec your result is measured in 10uS steps, according to the spec for your sonar, "If the pulse is measured in uS, then divide by 148 to get inches". So all you have to do is inchesright = rangeright/148. And inchesfront = rangefront/148.

Bookmarks